Powder Coating

Powder coating is a finishing technique where a fine, dry powder is applied to a surface using electrostatic principles. The powder, which may be either a thermoplastic or thermoset polymer, is electrically charged and sprayed onto the target surface. Once applied, the coating is cured at high temperatures, allowing it to melt, flow, and form a tough, uniform layer.

This process produces a finish that is more durable and resistant than most liquid paints.

Before the coating is applied, the surface must be thoroughly prepared.This preparation can be done chemically or mechanically to eliminate dirt, oil, old paint layers, and oxidation. Inadequate preparation can cause defects such as poor adhesion or uneven coating, since contaminants can interfere with bonding.

At Alfirdous, multiple cleaning techniques are used based on the part’s material, size, and condition. For steel and iron items, a phosphate treatment is typically followed by a drying process in the oven. For aluminum, an etching and degreasing process combined with chromate conversion ensures the surface is clean and properly conditioned.

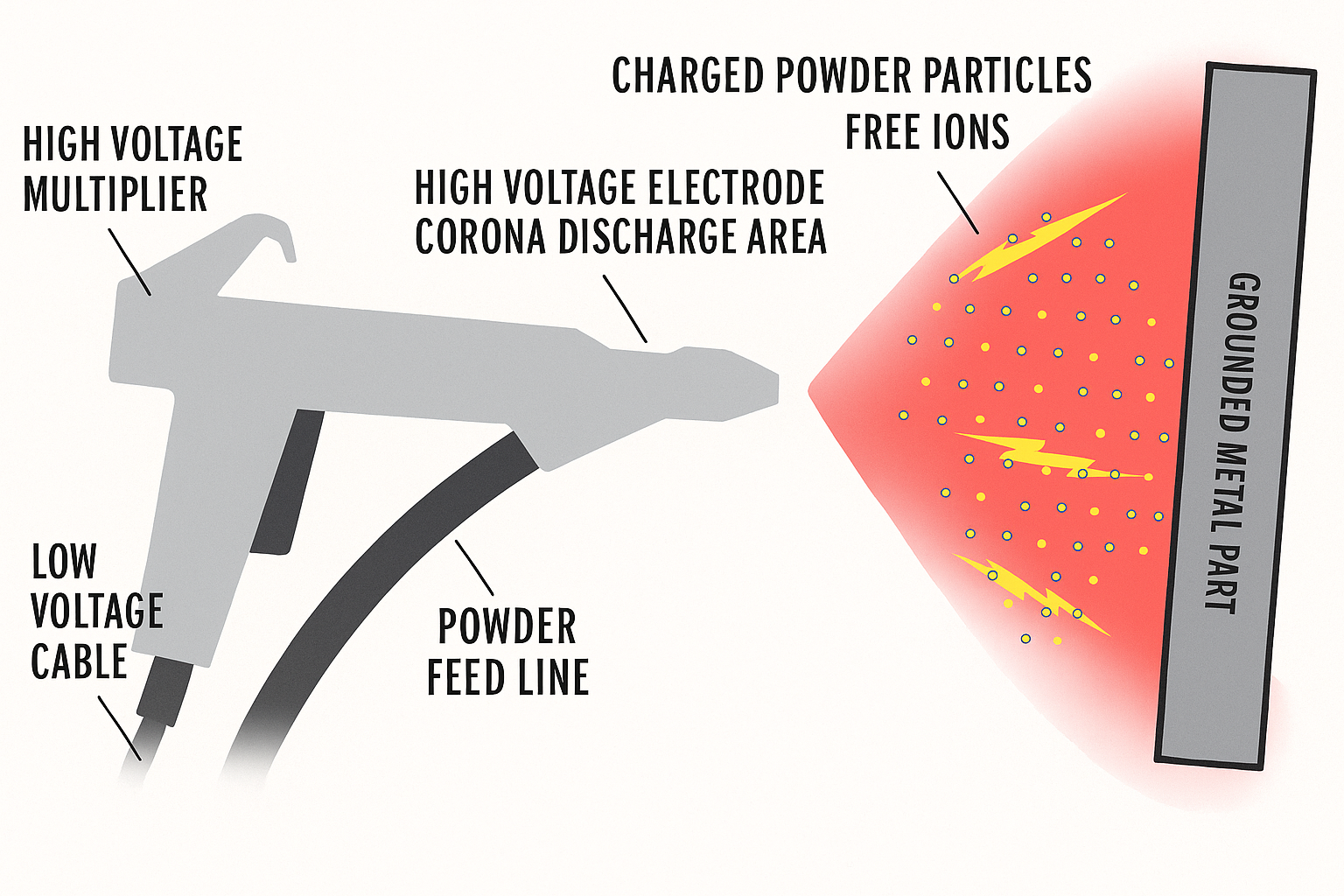

During application, the powder is sprayed with a compressed-air gun. As the powder exits the gun, it gains a positive charge, while the part being coated is grounded with a negative charge.

The electrostatic attraction causes the powder particles to adhere efficiently to the surface. Unlike liquid paints, powder coating minimizes overspray and waste because the particles are drawn toward the charged surface.

After the coating is applied, the part is baked in an oven at around 200–210°C. The curing time and exact temperature depend on the type of powder used and the size of the part.

A wide selection of powder types is available for various substrates and purposes. If a specific finish is not in stock, Alfirdous sources it on request. For projects where the best coating choice isn’t clear, expert guidance is available to select the right material for durability, appearance, and performance.